|

|

PDF HP2-AC6V Data sheet ( Hoja de datos )

| Número de pieza | HP2-AC6V | |

| Descripción | 10 AMP POWER RELAY | |

| Fabricantes | Panasonic | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de HP2-AC6V (archivo pdf) en la parte inferior de esta página. Total 13 Páginas | ||

|

No Preview Available !

www.DataSheet4U.com

Including discontinued products (

) HP

HP RELAYS10 AMP POWER RELAY

RoHS Directive compatibility information

http://www.mew.co.jp/ac/e/environment/

FEATURES

1. High-capacity and long life

Mechanical life is more than 10 million

operations and, with electrical life of more

than 200,000 operations (resistive load

10 A; inductive load 7.5 A), the relay has

excellent inductive load durability.

2. Easy mounting and wiring

The terminal arrangement is apparent at

a glance and wiring is easy. Moreover,

quick tab terminal is also possible.

3. Operation indicator option

Optional operation indicators are

available for easy visual confirmation that

relays are operating. They simplify

maintenance.

4. UL/CSA approved

5. Wide range of sockets and terminal

sockets

To enable use with DIN rails, DIN

terminal sockets are also available.

TYPICAL APPLICATIONS

HP relays enjoy wide use in various

applications, particularly in automation

controls and remote controls.

Applications include:

1. Industrial machinery

For controlling positioning, pressure, and

temperature in molding equipment,

boilers, pumps, charging pressure

equipment, measuring and evaluation

equipment, textile machines, etc.

2. Machine tools

Control of positioning and directional

change in turning machines, lathes,

borers, etc.

3. Food processing packing machines

Automatic control of packing equipment

for milk and seafood, bottling, canning,

and packaging

4. Office equipment

Control of copiers, time recorders, etc.

5. Coin operate machines

Control of food, cigarette, and other

vending machines

6. Transportation

Amplification of control signals in control

devices for vehicles and vessels,

functional parts of all kinds of equipment,

control signal repeating installation in

signaling devices and equipment.

7. Measuring devices and equipment

For repeating installation of control

signals and in power amplifiers

8. Generators, transformers and

power receiving equipment.

Functional parts in protective equipment,

functional assistance in automatic

adjustment equipment, telemeters and

other remote monitoring equipment

9. Control of conveyance equipment

Control panels for elevators, escalators,

and other conveyance equipment, control

of all kinds industrial transport equipment

such as conveyors.

10. Amusement equipment

Control of equipment in amusement

parks, etc., control of bowling alley

equipment, control of fountains in public

parks

About Cd-free contacts

We have introduced Cadmium free type

products to reduce Environmental

Hazardous Substances. (The suffix “F”

should be added to the part number. The

Suffix “F” is required only for 4 Form C

contact type. The 2 Form C and 3 Form C

contact type is originally cadmium-free,

the suffix “F” is not required.)

Please replace parts containing

Cadmium with Cadmium-free products

and evaluate them with your actual

application before use because the life of

a relay depends on the contact material

and load.

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

1 page

Including discontinued products (

)

HP

www.2D.aStapSehceiefit4cUa.tcioomns

Characteristics

Contact

Rating

Item

Arrangement

Initial contact resistance, max

Contact material

2 Form C, 3 Form C

4 Form C

Nominal switching capacity

Min. switching capacity (Reference value)*1

Insulation resistance (Initial)

Electrical

characteristics

Between open contacts

Breakdown voltage

(Initial)

Between contact sets

Between contact and coil

Temperature rise

Operate time*2

Mechanical

characteristics

Expected life

Conditions

Unit weight

Release time*2

Shock resistance

Vibration resistance

Mechanical

Functional

Destructive

Functional

Destructive

Conditions for operation, transport and storage*3

Max. Operating speed

Specifications

2 Form C, 3 Form C, 4 Form C

Max. 15 mΩ (By voltage drop 6 V DC 1A)

Ag

Ag alloy (cd free)

10A 250V AC (resistive load)

100mA 5V DC

Min. 100MΩ (at 500V DC)

Measurement at same location as “Initial breakdown voltage” section.

1,000 Vrms for 1min (2 Form C, 4 Form C).

2,000 Vrms for 1min (3 Form C) (Detection current: 10mA.)

1,500 Vrms for 1min (2 Form C, 4 Form C).

2,000 Vrms for 1min (3 Form C) (Detection current: 10mA.)

1,500 Vrms for 1min (2 Form C, 4 Form C).

2,000 Vrms for 1min (3 Form C) (Detection current: 10mA.)

Max. 65°C (By temperature method, at 40°C, nominal current)

Max. 25ms (2 Form C), Max.30ms (3 Form C, 4 Form C)

(Nominal voltage applied to the coil, excluding contact bounce time.)

Max. 25ms (2 Form C), Max.30ms (3 Form C, 4 Form C)

(Nominal voltage applied to the coil, excluding contact bounce time.) (without diode)

Min. 98 m/s2 (Half-wave pulse of sine wave: 11 ms; detection time: 10µs.)

Min. 980 m/s2 (Half-wave pulse of sine wave: 6 ms.)

10 to 55 Hz at double amplitude of 1 mm (Detection time: 10µs.)

10 to 55 Hz at double amplitude of 2 mm

Min. 107

Ambient temperature: –50°C to +40°C –58°F to +104°F

Humidity: 5 to 85% R.H. (Not freezing and condensing at low temperature)

20 cpm (at max. rating)

2 Form C: approx. 60g 2.12oz, 3 Form C: approx. 100g 3.53oz, 4 Form C: approx. 125g 4.41oz

Notes: *1 This value can change due to the switching frequency, environmental conditions and desired reliability level, therefore it is recommended to check this with the

actual load.

*2 For the AC coil types, the operate/release time will differ depending on the phase.

*3 The upper operation ambient temperature limit is the maximum temperature that can satisfy the coil temperature rise value. Refer to 6. Conditions for operation,

transport and storage mentioned in AMBIENT ENVIRONMENT.

3. Electrical life

1) AC load

Voltage

Load

125V AC

Resistive (A) (cosϕ=1)

Inductive (A) (cosϕ=0.4)

250V AC

Resistive (A) (cosϕ=1)

Inductive (A) (cosϕ=0.4)

— — 10 7.5

10 7.5 7.5

Current

533

5

2

1 0.7 0.6 0.4

Note: When the electromagnet or exciting coil (Solenoid, etc.) is the load, the value of motor or lamp load is applicable.

Expected life

Min. 2×105

Min. 5×105

Min. 106

Min. 2×106

2) DC load

Voltage

24V DC

Load

Resistive (A)

Inductive (A)

—7

Current

7.5

5

5

3

1 0.6

Note: For DC inductive loads, use an arc suppressing circuit.

Resistive (A)

—

0.5

0.3

0.1

125V DC

Inductive (A)

—

0.4

0.2

0.06

Expected life

Min. 2×105

Min. 5×105

Min. 106

Min. 2×106

Note: Cautions at DC load use

When used under a DC load operating at high repetition rate with considerable arcing, corrosion of the contacts and/or the contact blades is likely to occur.

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

5 Page

www.HDaPt4a-SShoecekt4eUt .(cHoPm4-SRS)

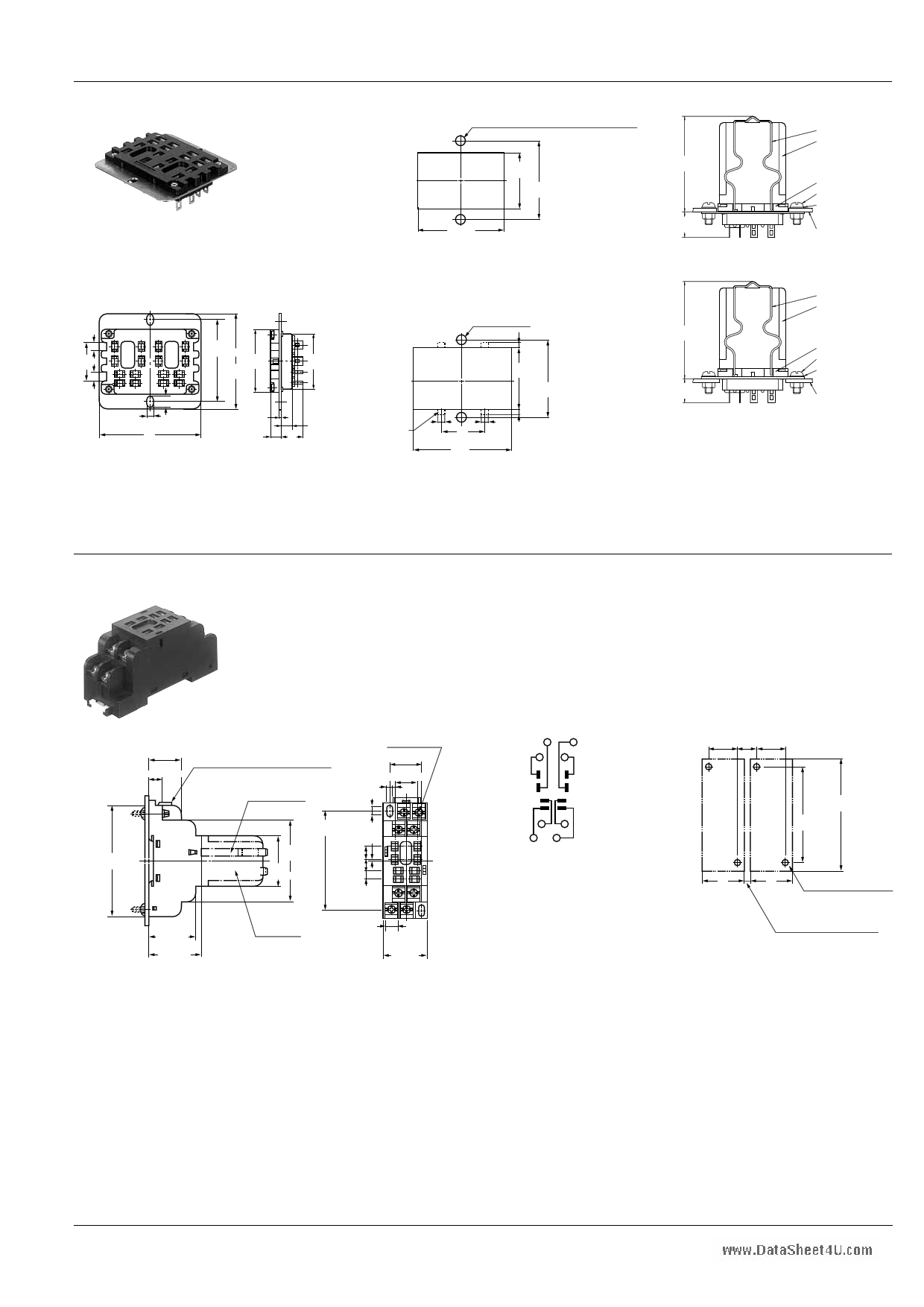

Front surface mounting

HP RELAY ACCESSORIES

Mounting dimensions

2-M4 screw hole (or 4.2±0.1 dia. hole)

2-M.157 screw hole (or .165±.004 dia. hole)

34

+1

−0

1.339

+.039

−0

48+−10

1.890+−.0039

48±0.5

1.890±.020

Tolerance: ±0.1 ±.004

52±3

2.047±.118

14

.551

Hold-down clip

HP relay

Socket

M4 screw

M.157

Spring washer

Panel (chassis)

5

.197

22

.866

5

.197

External dimensions

Rear surface mounting

2-4.2 dia. hole

2-.165 dia.

48±0.2

1.890±.008 38

56 1.496

2.205

33

1.299

4.1

.161

6.2

.244

58

2.283

1.0

.039 6

.236

13

5.5

.217

.512

General tolerance: ±0.1 ±.004

3

.118

39

+1

−0

1.535

+.039

−0

48±0.2

1.890±.008

3

.118

A

3

.118

25

.984

3

.118

58

+1

−0

2.283

+.039

−0

Tolerance: ±0.1 ±.004

* When using the former hold-down clip, it is necessary

to cut out the A section marked by the broken line

(not necessary with the powerful hold-down clip).

53±3

2.087±.118

13

.512

Hold-down clip

HP relay

Socket

M4 screw

M.157

Spring washer

Panel (chassis)

Notes: 1. Optimum space-saving panel cut-out.

2. Can be mounted from either the front or

the rear of the panel.

3. Hold-down clip is included in package.

2. Terminal socket for DIN rail assembly (hold-down clip and installation screw included)

HP2-Terminal socket for DIN rail assembly (HP2-SFD)

External dimensions

23.8±0.6

.937±.024

10±0.6

.394±.024

* Installation screw block

(installation screw, hexagonal nut,

spring washer)

Hold-down clip

M3.5 screw

M.138

22±0.6

.866±.024

4.1±0.3

4.1±.012

6±0.3

6±.012

15±0.2

.591±.008

80±1

3.150±.039

69±1

2.717±.039 0.6±0.15

.024±.006

58±1

9.5±0.2

2.283±.039 .374±.008

36±1

1.417±.039

7.5±0.2

.295±.008

5.8±0.2

.228±.008

33.8±0.6

1.331±.024

37.9±0.6

1.492±.024

HP2 relay

8±0.2

.315±.008

30±0.6

1.181±.024

Notes: 1. For direct mounting, use the included installation screw block.

2. A hold-down clip is included with the terminal socket.

Schematic

27

18

36

45

Mounting hole diagram

22±0.2 12±0.2 22±0.2

.866±.008.472±.008 .866±.008

80

3.150

69±0.5

2.717±.020

30 4

1.181.157

30

1.181

2-M4 screw hole

(or 4.2±0.1 dia. hole)

2-M.157 screw hole

(or .165±.004 dia. hole)

Panel hole dimensions

for side-by-side installation

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

11 Page | ||

| Páginas | Total 13 Páginas | |

| PDF Descargar | [ Datasheet HP2-AC6V.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| HP2-AC6V | 10 AMP POWER RELAY | Panasonic |

| HP2-AC6V | 10 AMP POWER RELAY | Panasonic |

| HP2-AC6V | 10 AMP POWER RELAY | Panasonic |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |