|

|

PDF MMBD2010T1 Data sheet ( Hoja de datos )

| Número de pieza | MMBD2010T1 | |

| Descripción | Switching Diode | |

| Fabricantes | ON Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de MMBD2010T1 (archivo pdf) en la parte inferior de esta página. Total 7 Páginas | ||

|

No Preview Available !

MMBD1010LT1

Switching Diode

Part of the GreenLine™ Portfolio of devices with

energy−conserving traits.

This switching diode has the following features:

• Very Low Leakage (≤ 500 pA) promotes extended battery life by

decreasing energy waste. Guaranteed leakage limit is for each diode

in the pair contingent upon the other diode being in a

non−forward−biased condition.

• Offered in four Surface Mount package types

• Available in 8 mm Tape and Reel in quantities of 3,000

Applications

• ESD Protection

• Reverse Polarity Protection

• Steering Logic

• Medium−Speed Switching

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Continuous Reverse Voltage

Peak Forward Current

Peak Forward Surge Current

DEVICE MARKING

VR 30 Vdc

IF 200 mAdc

IFM

(surge)

500

mA

MMBD1010LT1 = A5

MMBD2010T1 = DP

MMBD3010T1 = XS

THERMAL CHARACTERISTICS

Characteristic

Total Device Dissipation FR-4 Board (1)

TA = 25°C

MMBD1010LT1,

MMBD3010T1

MMBD2010T1

Derate above 25°C MMBD1010LT1,

MMBD3010T1

MMBD2010T1

Symbol

PD

Max

225

150

1.8

1.2

Unit

mW

mW/°C

Thermal Resistance Junction to

Ambient

MMBD1010LT1,

MMBD3010T1

MMBD2010T1

RθJA

°C/W

556

833

Junction and Storage Temperature

TJ, Tstg − 55 to +150

°C

(1) Device mounted on a FR-4 glass epoxy printed circuit board using the minimum

recommended footprint.

Preferred devices are Motorola recommended choices for future use and best overall value.

© Semiconductor Components Industries, LLC, 2006

August, 2006 − Rev. 2

1

http://onsemi.com

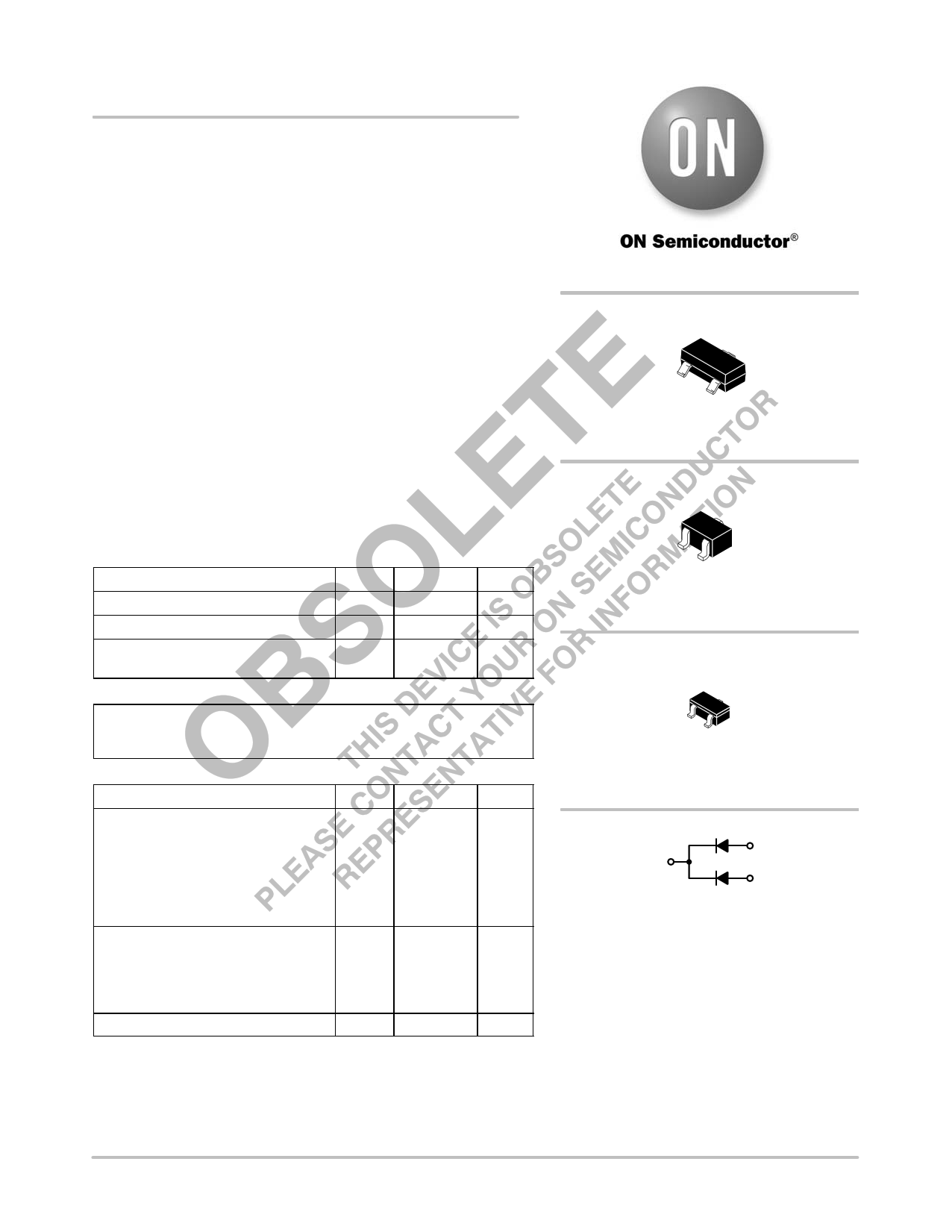

MMBD1010LT1

3

1

2

CASE 318-08, STYLE 9

SOT-23 (TO-236AB)

MMBD2010T1

3

1

2

CASE 419-02, STYLE 5

SC−70/SOT−323

MMBD3010T1

2

1

3

CASE 318D-04, STYLE 3

SC−59

3

CATHODE

ANODE

1

2

ANODE

Publication Order Number:

MMBD1010LT1/D

1 page

MMBD1010LT1

TYPICAL SOLDER HEATING PROFILE

For any given circuit board, there will be a group of

control settings that will give the desired heat pattern. The

operator must set temperatures for several heating zones,

and a figure for belt speed. Taken together, these control

settings make up a heating “profile” for that particular circuit

board. On machines controlled by a computer, the

computer remembers these profiles from one operating

session to the next. Figure 2 shows a typical heating profile

for use when soldering a surface mount device to a printed

circuit board. This profile will vary among soldering systems

but it is a good starting point. Factors that can affect the

profile include the type of soldering system in use, density

and types of components on the board, type of solder used,

and the type of board or substrate material being used. This

profile shows temperature versus time. The line on the

graph shows the actual temperature that might be

experienced on the surface of a test board at or near a

central solder joint. The two profiles are based on a high

density and a low density board. The Vitronics SMD310

convection/infrared reflow soldering system was used to

generate this profile. The type of solder used was 62/36/2

Tin Lead Silver with a melting point between 177 −189°C.

When this type of furnace is used for solder reflow work, the

circuit boards and solder joints tend to heat first. The

components on the board are then heated by conduction.

The circuit board, because it has a large surface area,

absorbs the thermal energy more efficiently, then distributes

this energy to the components. Because of this effect, the

main body of a component may be up to 30 degrees cooler

than the adjacent solder joints.

200°C

150°C

100°C

STEP 1

PREHEAT

ZONE 1

RAMP"

STEP 2

VENT

SOAK"

STEP 3

HEATING

ZONES 2 & 5

RAMP"

STEP 4

STEP 5

HEATING HEATING

ZONES 3 & 6 ZONES 4 & 7

SOAK"

SPIKE"

DESIRED CURVE FOR HIGH

170°C

MASS ASSEMBLIES

160°C

150°C

STEP 6 STEP 7

VENT COOLING

205° TO

219°C

PEAK AT

SOLDER

JOINT

100°C

140°C

SOLDER IS LIQUID FOR

40 TO 80 SECONDS

(DEPENDING ON

MASS OF ASSEMBLY)

DESIRED CURVE FOR LOW

MASS ASSEMBLIES

50°C

TIME (3 TO 7 MINUTES TOTAL)

TMAX

Figure 2. Typical Solder Heating Profile

http://onsemi.com

5

5 Page | ||

| Páginas | Total 7 Páginas | |

| PDF Descargar | [ Datasheet MMBD2010T1.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| MMBD2010T1 | Switching Diode | ON Semiconductor |

| MMBD2010T1 | Switching Diode | Motorola Semiconductors |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |